How Rigid Flex Circuit Boards Can Be Used in Medical Devices

Rigid Flex Circuit Boards Can Be Used in Medical Devices

Medical devices are specialized electronics that are used in a variety of applications. These devices need to be designed with a high level of reliability and durability, especially when they are used for human health. They also need to meet strict regulatory requirements for patient safety. The use of rigid flex circuit boards can help improve the performance and functionality of medical devices, allowing them to achieve their intended functions more efficiently.

rigid flex circuit can be used in a wide variety of medical device applications, but they are best suited for those that require a high degree of flexibility or where space is at a premium. For example, they can be used in wearable devices that are worn on the body to monitor vital signs or for treatment of chronic conditions such as diabetes. They can also be used in endoscopic or minimally invasive surgery devices to allow them to fit into tight spaces.

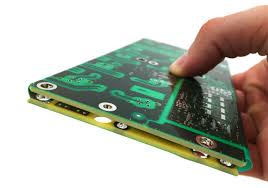

One of the most significant benefits of using rigid flex circuit boards in medical devices is their ability to provide a higher level of durability and reliability than traditional PCBs. This is because rigid flex circuit boards have a combination of rigid and flexible areas, which allows them to withstand dynamic bending or flexing while providing the structural integrity needed to ensure that medical devices are safe for human use.

How Rigid Flex Circuit Boards Can Be Used in Medical Devices

Another benefit of using rigid flex circuit boards in medical-related devices is their ability to eliminate the need for extra connectors and cables, which can increase the overall weight of the product. This can be a crucial factor in medical devices where reducing the amount of moving parts can lead to reduced maintenance costs and fewer potential points of failure.

Furthermore, rigid flex circuit boards can be designed to incorporate mounting components on both sides of the board, which is useful in medical device design when space is at a premium. This allows medical devices to be more compact and can even lead to a more aesthetically pleasing design.

In addition, rigid flex circuits can be designed with the conductive traces that are necessary for a medical device to function properly. This is because the conductive traces are etched into both the rigid and flex portions of the circuit board, which means that there are no surface-mounted electrical components to interfere with the medical device’s performance.

Medical-related device manufacturers who are interested in using rigid flex circuit boards in their products should work with a trusted PCB manufacturer who has experience with these types of designs. They can help them to select the best materials and manufacturing processes to ensure that their products are compliant with all regulatory requirements for medical devices.

Choosing the right PCB manufacturing partner is essential for any medical-related project. Working with an experienced company can help to speed up the development process and reduce costs and risks. They can also help to prevent any errors that may slow down the production process and increase the time-to-market for a finished product.